News + Trends

The Spanish brand Loewe makes T-shirts from ... orange peel

by Laura Scholz

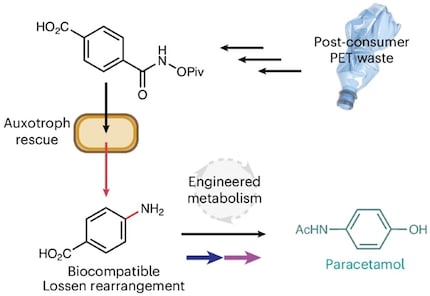

Researchers from Edinburgh have developed a process that turns PET waste into paracetamol. The process utilises bacteria.

Plastic waste is one of the biggest environmental problems of our time. PET is found in many everyday products, such as drinks bottles, packaging and textiles. Researchers from the UK have now shown that a useful active ingredient can be extracted from this waste: paracetamol. The research team has published the results in the scientific journal Nature Chemistry.

The scientists use living bacteria (E. coli) to break down PET into chemically smaller building blocks, from which they produce an amine compound using a process known as Lossen rearrangement. The bacteria then further convert the intermediate products using enzymes until paracetamol is finally produced.

According to the researchers, the manufacturing process achieves a purity of over 92 per cent. This means that paracetamol made from plastic could, in principle, be just as safe as conventionally produced paracetamol. However, even higher purities are often required for medicines, which is why further optimisation is necessary for industrial production.

Paracetamol is one of the world's best-selling painkillers. In Germany alone, over 8,000 tonnes are produced every year. Until now, production has mostly been based on crude oil as a raw material. The new approach could reduce dependence on fossil raw materials and make sensible use of plastic waste at the same time.

In addition, the recycling process could reduce the manufacturing costs of medicines. PET waste is available in large quantities worldwide and is often extremely cheap.

However, the British researchers emphasise that the process is not yet ready for industrial mass production. The yield is currently still too low and the chemical steps need to become more efficient. Nevertheless, they see great potential for the future.

My interests are varied, I just like to enjoy life. Always on the lookout for news about darts, gaming, films and series.